High Precision Lapping and Polishing Equipments

The facet optical coating process is a critical step in the manufacturing of high-power laser diode (LD) bars. These coatings, applied precisely to the resonator cavity facets (front and rear faces of the bar), serve essential functions: the front facet coating optimizes light emission efficiency, while the rear facet coating maximizes reflectivity to sustain the laser action within the cavity. High-quality, uniform coatings are paramount for achieving desired output power, efficiency, spectral characteristics, and long-term reliability. Imperfections or contamination during coating can lead to catastrophic optical mirror damage (COMD), drastically reducing device lifetime.

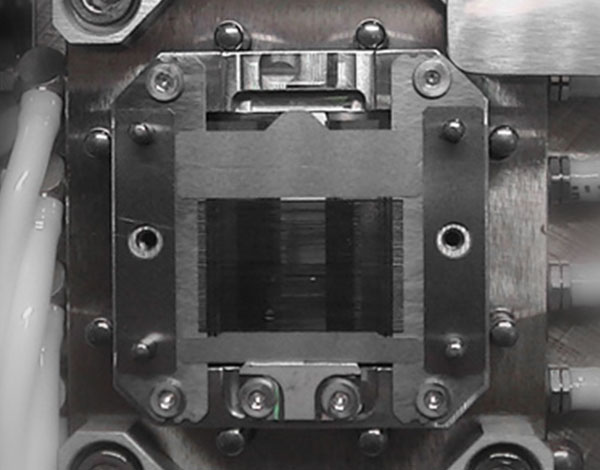

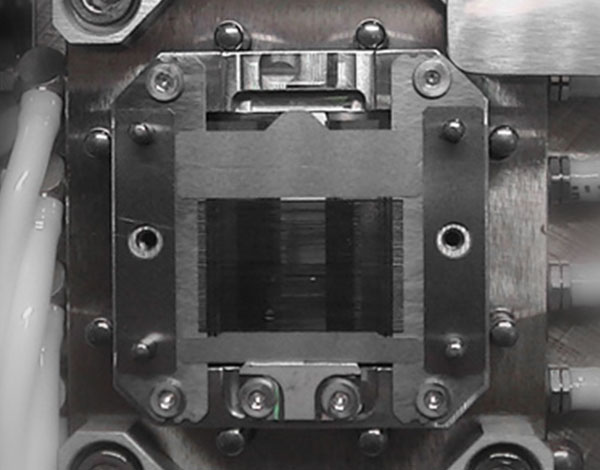

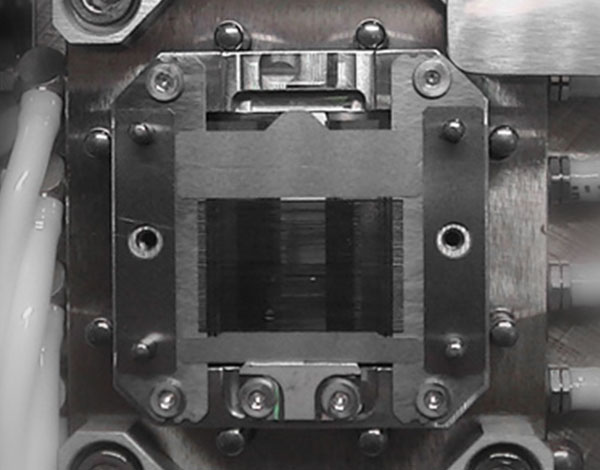

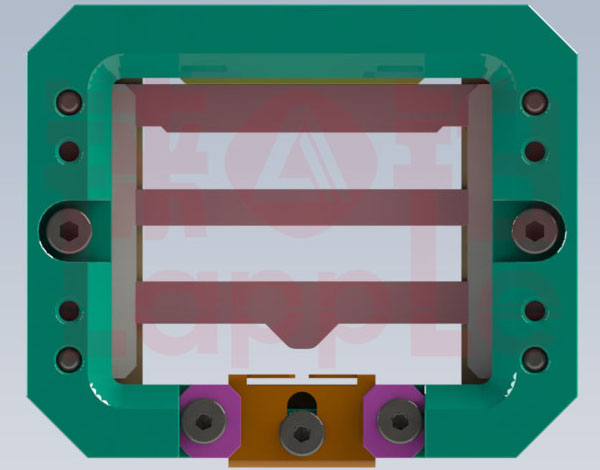

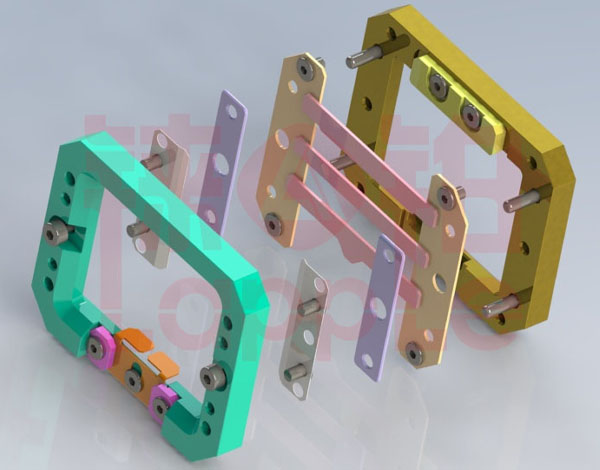

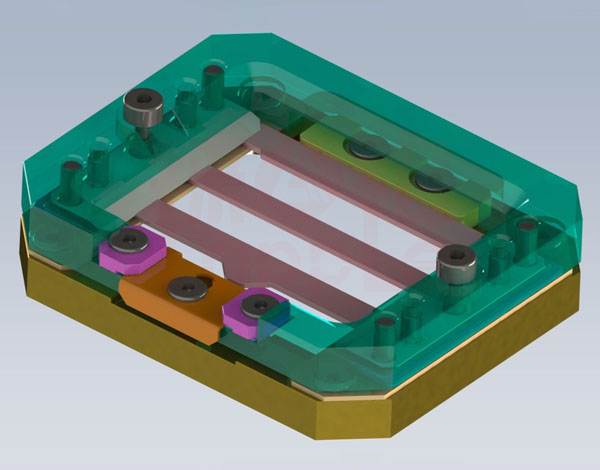

The successful application of these demanding optical coatings hinges on the use of specialized bar fixtures (or bar holders). These fixtures perform several vital roles during the coating process.

Crucially, the bar fixture must be meticulously customized to the specific dimensions and geometry of the LD bar being coated. Factors such as bar width, thickness (substrate height), cavity length, solder pad locations, and any existing wire bonds must be accounted for in the fixture design. A poorly fitting or non-custom fixture can lead to Stress Points,Misalignment,Poor Thermal Contact,Contamination and Reduced Yield & Reliability.

Therefore, the design and fabrication of custom bar holders tailored precisely to the LD bar's dimensions are not merely beneficial but essential for achieving high-performance, reliable optical coatings. The fixture acts as the critical interface between the delicate semiconductor device and the demanding coating environment, directly impacting the quality and consistency of the final high-power laser diode bar product.

The fixture rigidly holds the LD bar, ensuring its facets are perfectly perpendicular to the coating vapor flux within the deposition chamber.

The fixture provides mechanical stability, minimizing any movement or vibration that could disrupt the delicate deposition process or cause bar misalignment.

Fixtures often incorporate thermal paths or cooling channels to manage the heat load absorbed by the bar during the energetic deposition processes, preventing thermal damage.

They facilitate safe handling of the fragile bar into, within, and out of the vacuum chamber, protecting the delicate facets and wire bonds.

| Materials | Bar Cavity Length | Bar Width | Bar thickness | Clamping force | Quantity per fixture |

|---|---|---|---|---|---|

| GaAs,InP... | 4mm...... | 10mm.... | 150um+/-15um..... | Low force spring clamps(<3N)... | 1 active bar+2dummy bars.... |