High Precision Lapping and Polishing Equipments

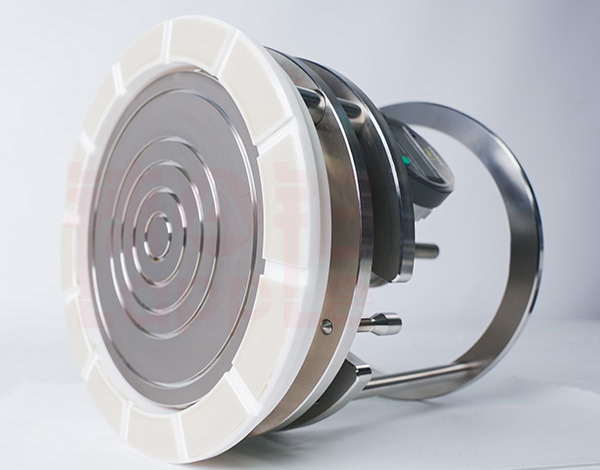

Lapple Precision Jigs represent the pinnacle of sample holding technology for demanding lapping and polishing applications. Designed for researchers and technicians requiring the highest levels of control and repeatability, these jigs provide a robust and versatile platform for preparing diverse specimens.

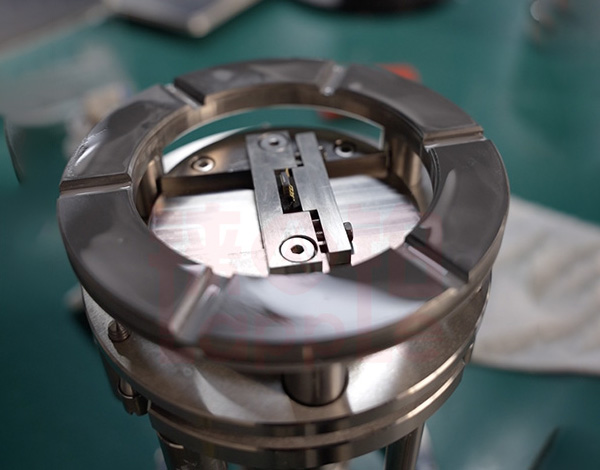

Precision-engineered and meticulously hand-finished, Lapple jigs ensure exceptional accuracy during material removal processes. They accommodate an extensive range of sample sizes, geometries, and material types – from delicate, fragile specimens to robust, hard materials. Secure sample retention is achieved through multiple methods: reliable mechanical fixing, direct wax mounting, or efficient vacuum hold-down. Precise planar alignment is facilitated by an integrated angular adjustment plate, guaranteeing optimal sample orientation.

In essence, Lapple Precision Jigs deliver unmatched ease of operation, exceptional accuracy, and adaptable sample handling – empowering precise material preparation for the most challenging applications.

Easily vary sample load from 200 grams to 10 kilograms, tailored to material requirements and specific jig models.

Specifically designed for compatibility with aggressive polishing solutions, including sodium hypochlorite-based chemistries like Lapple's 'Chempo'.

Features a wireless digital display gauge with outstanding accuracy within 1 micrometer (1µm). Plate will automatically stop when the pre-set target material removal thickness is achieved.

A comprehensive range of jig models caters to virtually any sample dimension or material hardness encountered in advanced laboratories.

| Vacuum Jig | PP3 3" | PP4 4" | PP6 6" | PP8 8" | Description |

|---|---|---|---|---|---|

Chuckface Diameter |

83mm | 112mm | 162mm | 212mm | Special sizes can be customized. |

TTV after sample process |

+/-2um | +/-3um | +/-4um | +/-5um | Better TTV also can be reached. |