High Precision Lapping and Polishing Equipments

Precision surface preparation is paramount in semiconductor manufacturing. Our specialized Lapple lapping and polishing plates are engineered to meet the extreme demands of processing semiconductor wafers (Silicon, SiC, GaAs, GaN, InP, Sapphire,MCT,CZT,InSb....) and critical components. They provide the essential foundation for achieving ultra-flat, damage-free surfaces with nanometer-level precision required for subsequent lithography, deposition, and inspection stages. Selection of the optimal plate material and groove pattern is critical based on the substrate material, wafer size (e.g., 150mm, 200mm), process stage (rough lapping, fine lapping, polishing), and desired surface finish.

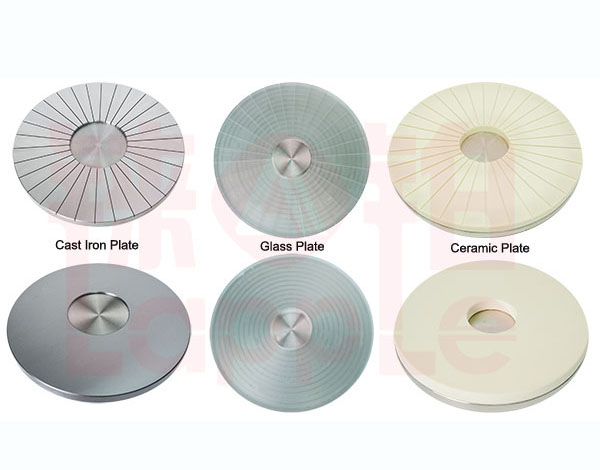

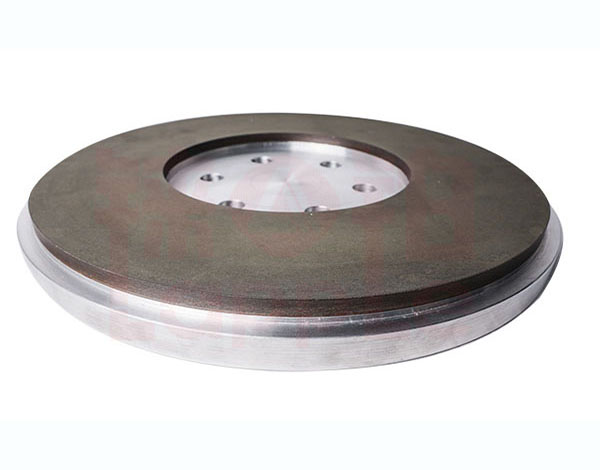

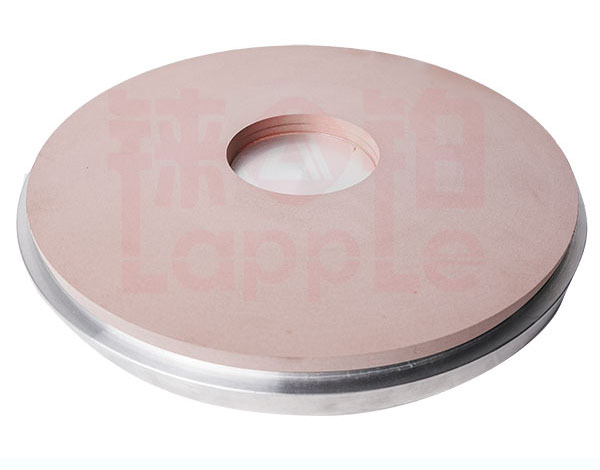

Diverse High-Performance Materials: Engineered for specific applications: Fine-Grain Cast Iron: Industry standard for roughing/fine lapping. Excellent cut rate, stability, and wear resistance. Requires conditioning.Glass/Ceramic: Superior chemical resistance and thermal stability for demanding CMP slurries and processes. Maintains exceptional flatness.Resin-Bonded Diamond: Extremely hard and durable. Ideal for ultra-hard materials like Diamond,SiC, Sapphire, and advanced compound semiconductors. Provides aggressive cutting with controlled wear.Resin-Copper/Resin-Tin: Soft, resilient matrices used in final polishing stages. Minimizes subsurface damage and achieves ultra-smooth, mirror-like finishes essential for device layers.

Manufactured to micron or sub-micron flatness specifications. Essential for achieving uniform material removal.

Concentric,radial,crosshatch/grid grooves are critical for slurry distribution, debris removal, heat dissipation, and pressure control.

Engineered to minimize subsurface damage, micro-cracks, and scratches during material removal, preserving wafer integrity and device yield.

High-quality materials and precision manufacturing ensure long service life and consistent performance batch-to-batch, reducing consumable costs and process variability.

| Materials | Cast Iron | Glass | Ceramic | Resin Diamond/Copper | SS/PU pad/S800/C1000 |

|---|---|---|---|---|---|

Plate Diameter |

300mm | 350m | 400mm | 500mm | Special sizes can be customized. |

Plate TTV |

300,+/-2um | 350,+/-3um | 400,+/-4um | 500,+/-5um | Better TTV also can be reached. |