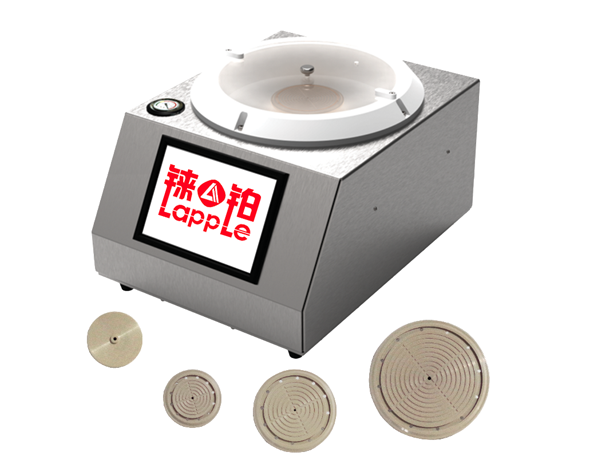

High Precision Lapping and Polishing Equipments

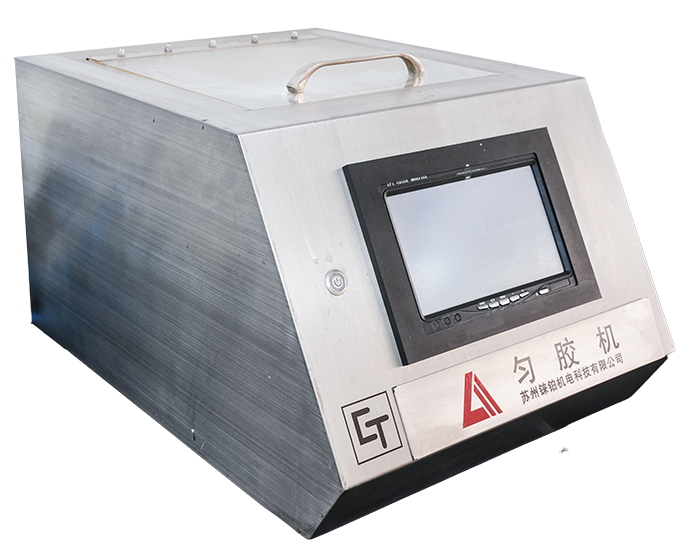

SC61 is a desktop programmable Spin Coater, easy and convenient to operate. For liquid wax coating and wafer bonding.Wafer size up to 6". Touch Screen. A spin coater is a device that drips various types of glue/wax onto a high-speed rotating substrate, and uses centrifugal force to evenly coat the glue onto the substrate. The thickness of the film depends on the speed of the spin coater and the viscosity of the liquid wax. Spin Coating Process 1. Drop by drop. When the wafer is stationary or rotating very slowly, liquid wax is dripped onto the wafer; 2. Rotate and spread out. Quickly accelerate the rotation of the wafer to a high speed (rpm) to extend the wax to the entire surface of the wafer; 3. Rotate and shake off. Remove excess wax and obtain a uniform wax film coating on the wafer; 4. Solvent evaporation. Continue rotating the coated wafer at a fixed speed until the solvent evaporates and the wax film is almost dry.

300~8000rpm.

0~200s.

Can be freely set in ten sctions.Uniformity better than ± 2%

Fully automatic.PEEK tray for fragments to 6" wafers.PP cavity with disposable lining

| Wafer Size | Up to 150mm in diameter |

|---|---|

| Speed | 300~8000rpm |

| Timer | 0~200s |

| Program | Can be freely set in 10 sections. |

| Throughput | Depends on the process |

| Tray and Cavity | peak tray for fragments to 6inches.PP cavity with disposable lining |

| Power Requirements | 220V, 10A |