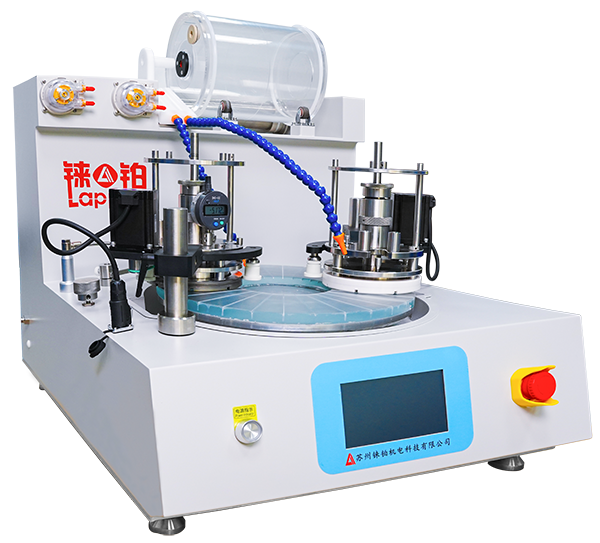

High Precision Lapping and Polishing Equipments

The LP062 precision lapping and polishing machine is a two workstations desktop type, suitable for small-scale production of lapping and polishing. It can complete the processing of samples with a size of 6 inches or less, and the processed samples have characteristics such as high flatness and high surface finish. In the fields of semiconductor, optoelectronics, optics and other applications. All functions of LP062 lapping and polishing machine, including plate speed, swing arm setting, abrasive feeding are controllable, and these functions and parameters are all controlled and set through the touch screen.

Achieves surface flatness down to 1μm and roughness Ra less than 1nm

Different plates to meet different applications

Efficient plate shape control to prevent bad TTV

Can be used for lapping and polishing,for different size of samples,different applications on same system

| Plate Size | 400mm |

|---|---|

| Number of Workstation | 2 |

| Plate Surface Flatness | ≤3μm |

| Final Sample Surface Roughness | Ra≤1nm,depending on process and materials |

| Sweep Arm | Driven jig roller arm with sweep,sweep speed and driven speed adjustable |

| Platen Speed | 0~100rpm |

| Abrasive Feeding | Cylinder with two Peristaltic Pumps. |

| Power Requirements | 220VAC, 10A |

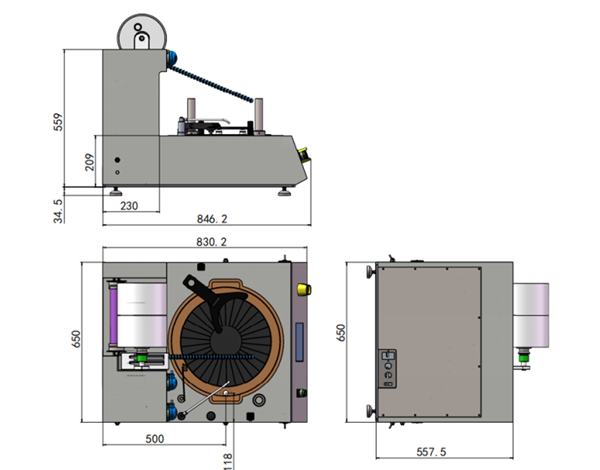

| Dimensions and Weight | 830×650×660mm (L×W×H),60KG |