High Precision Lapping and Polishing Equipments

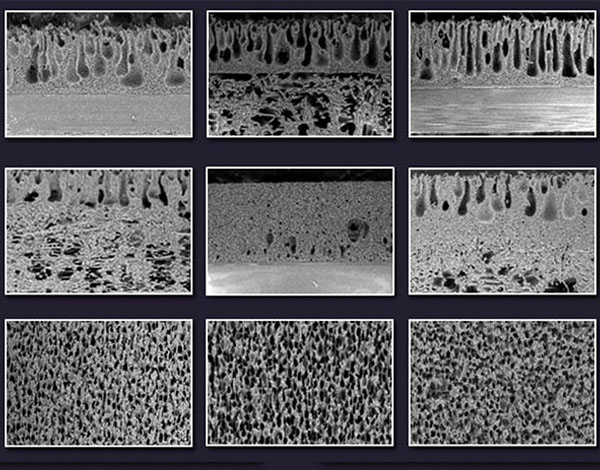

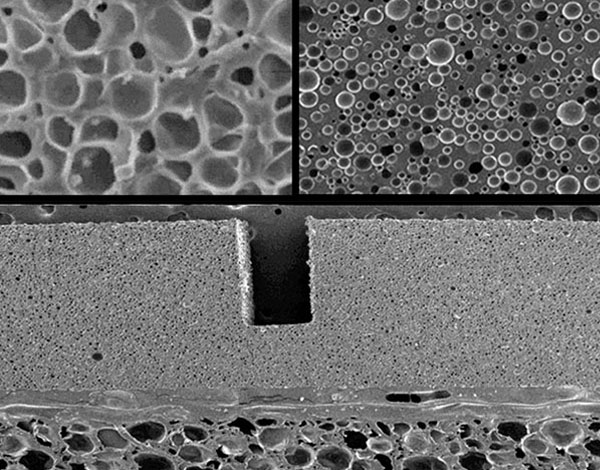

Our advanced LP series polishing pads are engineered for high-performance polishing process in semiconductor manufacturing. These pads provide exceptional polishing efficiency, extended pad life, and low defectivity for a wide range of materials including Silicon, GaAs, InP, GaN, Sapphire, Ceramic, SiC, LiNO3, copper, ILD, STI,etc.

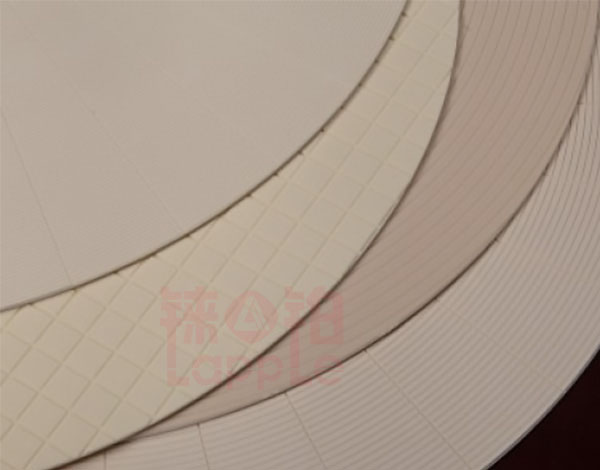

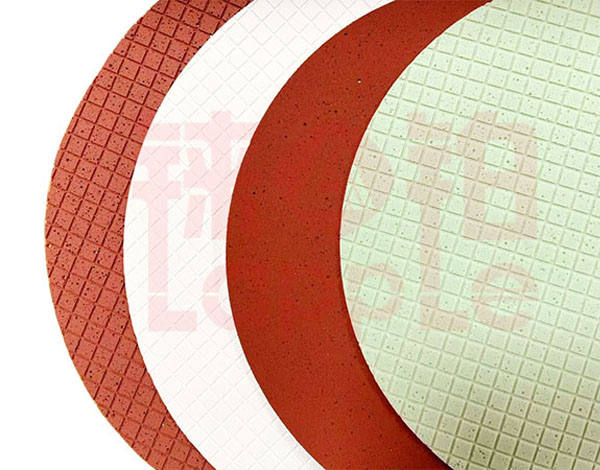

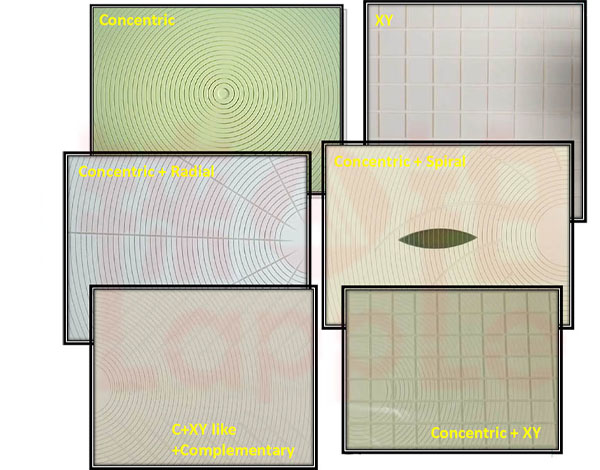

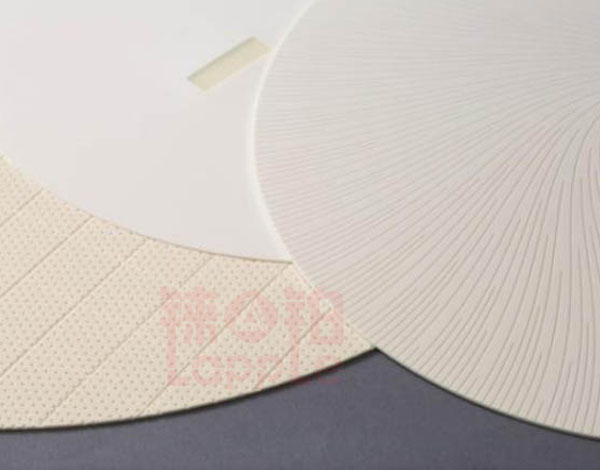

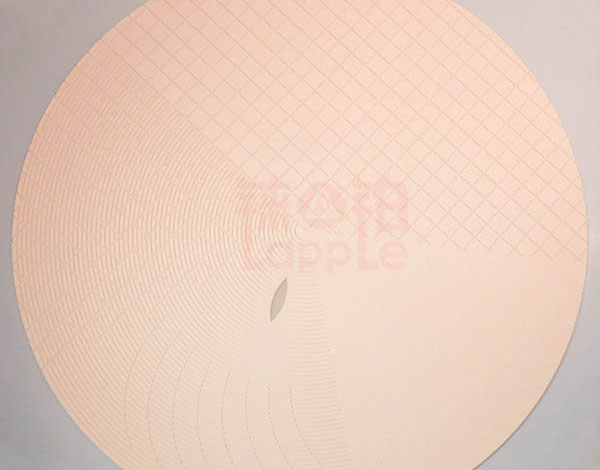

Optimized groove patterns for superior material removal rates

Durable polymer formulation for longer pad life and reduced cost

Precision engineered surface minimizes scratches and defects

Uniform pad properties for stable process results

| Type | Material | Density(g/cm3) | Hardness | COMPRESSIBILITY | Applications |

|---|---|---|---|---|---|

| LP-EP1 | Expanded polyurethane | 0.7 | 95-97 Shore A | 7~8% | Sapphire,Silicon,CMP Titanium |

| LP-EP2 | Expanded polyurethane | 0.6 | 86-88 Shore A | 9~10% | Precision optics,Silicon,semiconductor substrate etc. |

| LP-EP3 | Expanded polyurethane | 0.78 | 95-97 Shore A | 7~9% | Glass,Crystal, Precision optics,Silicon,semiconductor substrate etc. |

| LP-Chemtex | Poromeric | 0.48 | 54 Shore A | 6-24% | GaAs,InP,LiNO3,Silicon,lithium tantalate, nickel, polysilicon,tungsten, zerodur |

| LP-S800 | Felt | 0.47 | 82 Asker C | 3~4% | Sapphire, silicon carbide, gallium nitride, silicon nitride, silicon |

| LP-C1000 | polyurethane | 0.8 | 52~62 Shore D | 0.5~4% | Sapphire, silicon carbide, gallium nitride, silicon nitride, silicon, copper, ILD, STI. |