High Precision Lapping and Polishing Equipments

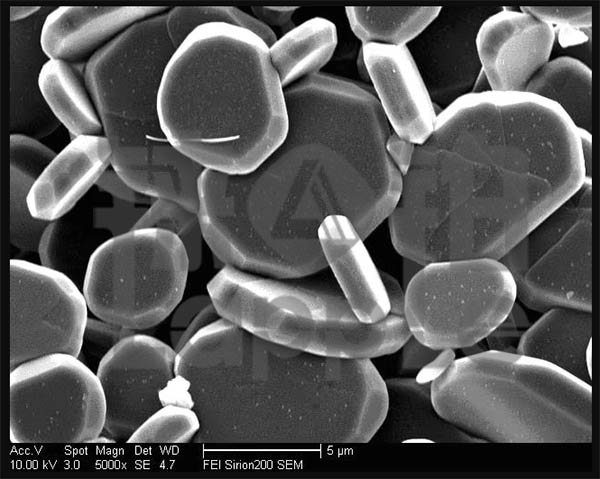

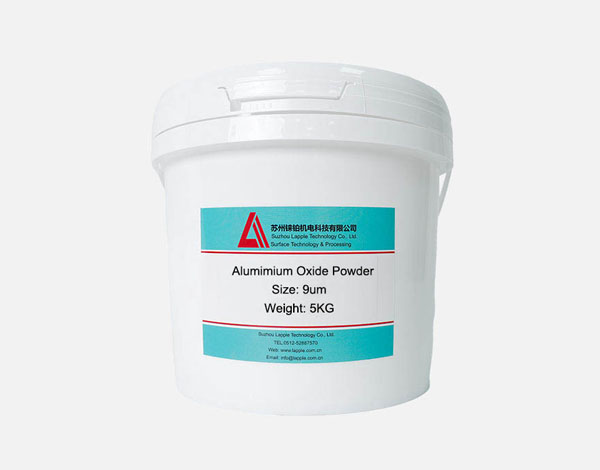

Lapple LCA series aluminium oxide Powders are manufactured in a time proven high tech and unique process that offers performance, dependability and consistency,and its grades particles in sizes and shape more closely than possible by normal means. This makes it especially effective when used on hard and soft materials such as ceramics,silicon and GaAs,InP etc.The particles produced by this process are flat, and tend to lie parallel to the surface being processed. Due to the close grading and flat particle shape, LCA aluminium oxide powders are suitable for a wide range of precision lapping and polishing operations and offer many advantages.

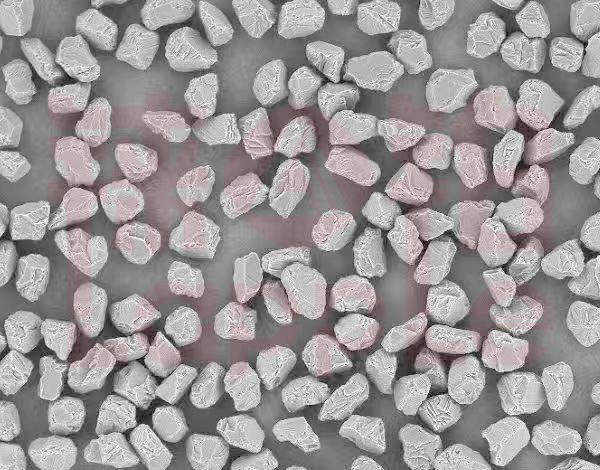

Lapple SiC Powder is made by a precision water classification process using material that is produced from the reaction between high purity silica sand and petroleum coke in a resistance-type furnace. Measuring 9.0+ on the MOHS scale of hardness, silicon carbide is one of the hardest abrasives known in the industry. The inherent friability of the sharp crystalline structure assures the continuous exposure of new cutting edges, which produces a faster and cleaner cutting performance.Lapple SiC powders are precisely graded to the particle size specifications set.

Lapple Boron Carbide Powders are manufactured from carbon crude having very low free graphite content, then water classified to the highest quality standards. Its Knoop hardness of around 3000 makes them suitable for such applications as: lapping of hardened tools, valves and seats; and lapping of ceramics and minerals which are too hard to be worked with silicon carbide.Lapple Boron Carbide has exceptional properties in Sapphire and SiC wafers lapping slurries.

Lapple's HQ(high-quality)series Cerium Oxide (CeO2)powders are used for polishing glasses, lenses, optics, ceramics and wafers etc..Lapple's premium Cerium Oxide powders have good suspension and well-controlled particle size distribution, which allows you to produce excellent surface finish in a highly effective way.It has a high melting point and hardness, making it suitable for high-precision polishing tasks. It is also chemically stable and resistant to alkalis and moderate acids. High-quality cerium oxide powder is available in purities ranging from 99% to 99.99%, ensuring excellent performance in various polishing applications. It is typically used in slurry form for effective polishing, with particle sizes ranging from 0.3 µm to 10 µm.

Lapple Diamond Polishing Powders offer the ultimate in quality and economy of operation and can be used with a wide variety of soft metal polishing plates and polishing cloths.

Engineered to strict particle size distributions enabling superior control over material removal rates and final surface quality.

Consistent chemical composition, morphology (shape), and hardness across the batch ensure stable, predictable, and repeatable process results.

Offers a balance between cutting efficiency and the ability to achieve fine finishes, minimizing surface damage.

Provides an excellent balance of performance and cost

| Code | Powder | Particle size | Color | Pack size | Applications |

|---|---|---|---|---|---|

| LCON-PD001... | Aluminium Oxide | 1um~50um,ultrafine1.0,0.3,0.05 | White | 5Kg,20KG | Silicon,Sapphire,Ceramic,GaAs,InP,MCT,CZT,LiNO3.... |

| LCON-SiC1500... | Silicon Carbide | 1500grit~240grit | Dark Grey | 5Kg,20KG | Silicon,Sapphire,GaN,Ceramic,Diamond,GaAs,InP,MCT,CZT.... |

| LCON-SI001 | Cerium Oxide | 3um,1um,0.5um | Cream | 2Kg,10KG | Silicon,Sapphire,GaN,Ceramic,GaAs,InP,MCT,CZT,LiNO3.... |

| LCON-BC1500... | Boron Carbide | 1500grit~240grit | Black | 1Kg,5Kg,20Kg | Silicon,SiC,Sapphire,Ceramic,GaAs,InP,MCT,CZT,LiNO3.... |

| LCON-DID001... | Diamond | 0.1um~50um | Grey White | 100g,500g,1000g | Silicon,Sapphire,GaN,Ceramic,diamond,SiC,GaAs,InP,MCT,CZT,LiNO3.... |