High Precision Lapping and Polishing Equipments

Our advanced CMP polishing pads are engineered for high-performance chemical mechanical planarization in semiconductor manufacturing. These pads provide exceptional planarization efficiency, extended pad life, and low defectivity for a wide range of materials including silicon, silicon dioxide, copper, and low-k dielectrics.

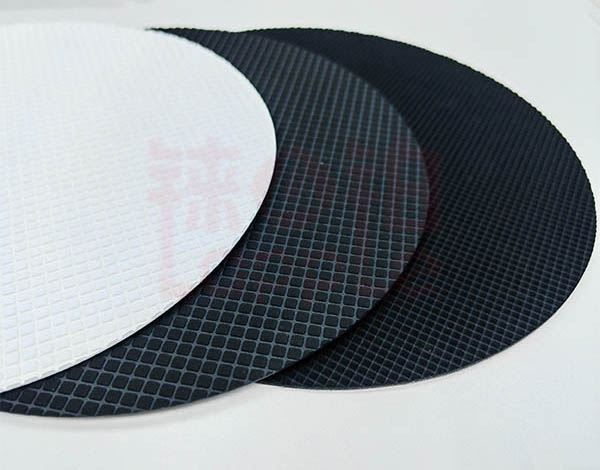

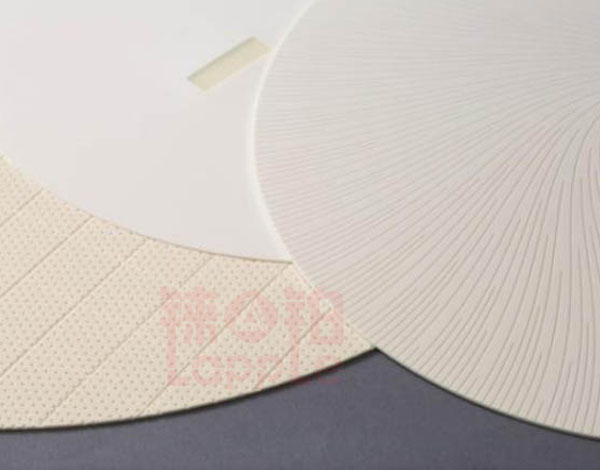

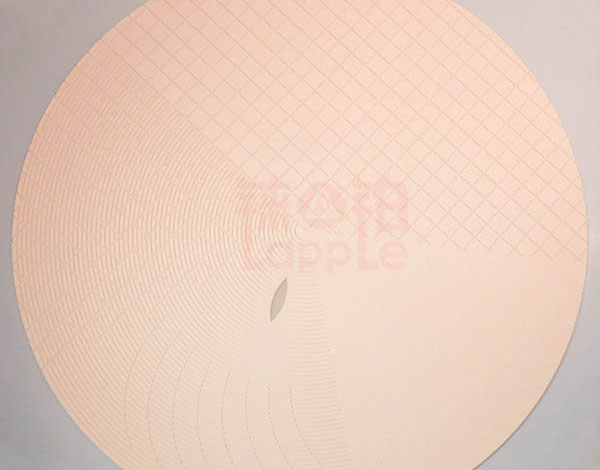

IC1000™ pad is the industry-standard polishing pad for chemical mechanical polishing (CMP). The IC1000™ pad is made of a rigid, micro-porous polyurethane material. These properties enable the IC1000™ pad to deliver localized planarization, excellent removal rates, low global non-uniformity and low defectivity. The IC1000™ pad works effectively with slurries and conditioners to optimize CMP performance in tungsten, copper, ILD, STI, and polysilicon processes.

POLITEX™ polishing pad was originally developed for final wafer polishing. It is manufactured from proprietary polyurethane and incorporates a unique, vertically oriented pore structure with a compressible substrate. The substrate is designed to instantaneously recover from polishing compression, creating a pumping action that enhances slurry low within the pad to produce optimum surface finish quality. This attribute reduces pad loading and increases pad life, which is well suited for final polishing of silicon, oxide, glass or metals.

SUBA™ polishing pads are polyurethane impregnated polyester felts. They are specifically designed for stock and intermediate polishing where achieving a high precision surface is critical. SUBA™ pads should be used in combination with each other and with final polishing pads to produce a haze-free, low defect finish in dual or multi-step processes. SUBA™ pads are ideal for a wide variety of materials including semiconductor wafers, glass, ceramics, special metals and plastic. SUBA™ IV features an open pore structure and a less aggressive urethane composition than the other SUBA™ pads. These qualities make it an ideal primary polishing pad for low to medium pressure applications with fragile crystals or delicate surfaces.

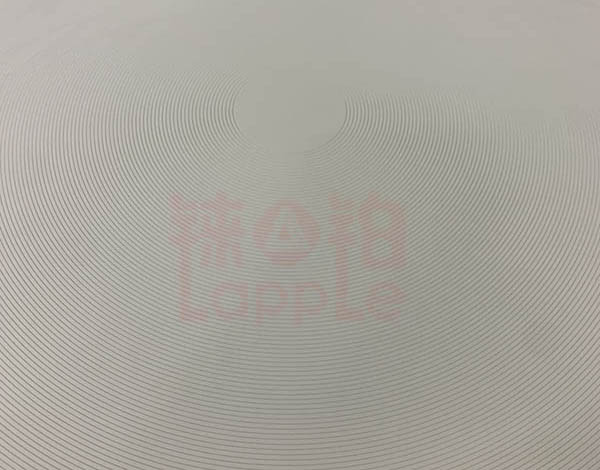

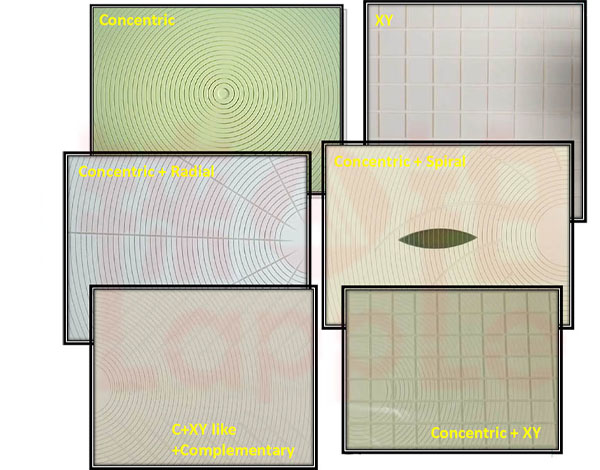

Optimized groove patterns for superior material removal rates

Durable polymer formulation for longer pad life and reduced cost

Precision engineered surface minimizes scratches and defects

Uniform pad properties for stable process results

| Model | Base Material | Compressibility | Hardness | Thickness (mm) | Applications |

|---|---|---|---|---|---|

| IC1000 | Urethane | 2.0-2.5% | 58-60 Shore D | 1.27 | Nickel, Polysilicon, Tungsten, Copper, ILD, STI |

| IC1010 | Urethane | 2.0-2.5% | 58-60 Shore D | 2.03 | Nickel, Polysilicon, Tungsten, Copper, ILD, STI |

| POLITEX | Poromeric | 13.5-15.0% | 55-60 Shore D | 1.50 | indium phosphide, lithium niobate, lithium tantalate, nickel, polysilicon, silicon, tungsten, zerodur |

| Suba-800 | Felt | 4.0% | 82 Asker C | 1.27 | Sapphire, silicon carbide, gallium nitride, silicon nitride, silicon |

| Suba-IV | Felt | 13.5% | 44 Shore D | 1.27 | Sapphire, silicon carbide, gallium nitride, silicon nitride, silicon |